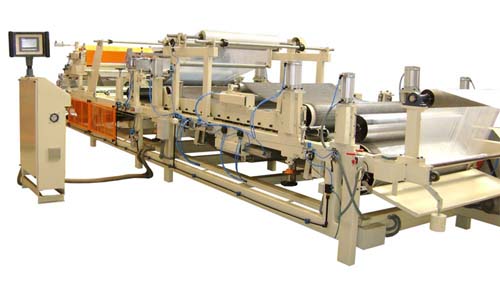

Sheet Molding Compound Machine

| Business Type | Manufacturer, Exporter, Supplier |

| Compound Width | up to 1200mm |

| Compound Weight | 2.5 – 6.0 Kg/m² |

| Glass Content | up to 50% * (Using Double Chopper Head)With Strand length 1/2” – 2” |

| Click to view more | |

Preferred Buyer From

| Location | Anywhere in India |

Product Details

Sheet molding compound (SMC Machine) is a process as well as reinforced composite material. The composite is a “ready to mould” glass and other fibre reinforced polyester resin material mainly used in compression moulding. The compound is produce in rolls and zigzag winding shapes, SMC compound is manufactured by uniform distribution of chopped strand glass or other fibres in required proportion by weight over moving carrier film having layer of resin compound from upper and lower doctor box.

Mix matrix is then impregnated by passing through upper and lower set of rollers with control pressure and after final impregnation compound sheet is collected at the winder either by roll winding or zig-zeg winding for further storage and use.

Compound sheet can be produce with following variables,

- Compound sheet width and thickness

- Compound sheet unit area weight

- Percentage of glass / other reinforcement in compound sheet

- With different strand length as per product requirement

Composite SMC has many important areas of applications as under,

Automotive parts, high-strength electrical parts, Switchgear body, Meter Box, Junction Box, Panel Enclosure, Motors Shrouds, Generator Enclosures, Panel Tank Components, Railway Coach Components, Military & Aerospace, Transportation, Safety, Medical, Electrical, Oil & Gas, Alternative Energy, Marine, and various structural components.

SMC Machine Features:

- Precision tubular machine structure with epoxy primer and PU paint.

- Precision machine components with required protective coating.

- Life lubricated gear reduction drives.

- PLC, HMI, AC Drives for machine operation and control.